Products >> ClearVu Fencing

The 'Clearvu'- style high security galvanized fence. The fence shall be a single-layer welded mesh design with minimum 4milimiters (mm) of horizontal and vertical circumference wires (horizontal wires to be on the attack side);

The resulting mesh dimension shall not be larger than 76mm wide by 13mm high;

The length of each fence panel shall be 2.5m

Barbed tape concertina with seven clips per spiral and short blades at 25mm centres;

4

MESH SIZE (Aperture)

A: 50*76.2mm(Basic Option)

B: 25*76.2mm(Standard Option)

C: 12.7*76.2mm(Premium Option)

A Basic Option |

B Standard Option |

C Premium Option |

Three opinions for rigid.

A: 3D OPTION

B: 2D OPTION

C: 2D with additional wire

A: 3D OPTION |

B: 2D OPTION |

C: 2D with additional wire |

Clear View Fencing POST:

A: Square post: 60*60mm

B: Round Post: φ60mm

C: "I " Post: 70*44mm

D: IPE POST:100*55MM

A Square post |

B Round post |

C "I" Post |

D IPE POST |

CONNECTION

- A: Spider Clamp with square Post

- B: Spider Clamp with IPE post (Double quantity clamps)

- C: FLAT BAR with Square post

A: Metal Spider Clips |

B |

C |

Clear View Fencing Spider Clamp

A |

B |

C |

8

POST CAP:

- A: anti-UV plastic cap

- B: metal cap

Anti-UV plastic cap |

Metal cap |

Advantages Clear Fencing :

- The aperture is 72.2mm horizontal x 8.7mm vertical, making Clearvu security fencing extremely difficult to penetrate using conventional hand tools, thus providing a high delay factor.

- Despite the high degree of security, the visual impact of a Clearvu fence on the environment remains very discreet. It is specifically give maximum visibility (important for clear camera surveillance and identifying intruders.)

- Clearvu security fencing is designed for compatibility with electronic alarm and detection systems. The Weld strength of this kind of security fencing is a minimum of 75% steel strength guaranteed on every weld.

Surface treatment clearvu Fencing:

Zinc Class A (min. 275g/m²) or Class C (110g/ m²) - coated - PVC Coating Optional. Heavy galvanized wire Class A (min. 275g/m²) or Lightly Galvanizedz wire Class B (min. 135g/m²) - coated - PVC Coating Optional.

Africa customer case

We supply high-security Clearvu mesh fence with an Electric fence system. Clearvu Mesh with 1600 x 80x60x4mm RHS posts and 50 x 80x60x4mm RHS posts with 250x250x10mm base plates and M20 mounting holes. 6x6 meter double swing gates with heavy-duty mounting posts and swing 380Vac motors for automation.

The fence is galvanized, PVC powder coat in RAL 6005 green colour, including the electric fence posts. Insulators need to be in military green.

Also, include 300mm "Y" standard posts with 4x 10mm holes and 100mm centres covering 3700 meters, 1600 x 1300 meters in height. Also, include 20,000 meters of 8mm steel rope to be mounted with "Y" standard posts.

Technical Specification

The supply, manufacture and delivery to site, installation and commissioning of a complete 2.4m high x 3700m long perimeter security anti-climb fence with a 3.4m high multi-zone Electric fence system. The fencing system shall be installed with all the components that enable it to function.

Site-specific construction requirements

- Where required, all existing physical fence strain points will be replaced with a fit-for-purpose SHS post of suitable height, and section 10 supports the entire length of the Post. Where possible, the Post will be prefabricated with the physical Post with a hot-dipped galvanized finish.

- Each linear zone may be split into two vertical fence channels, upper and lower.

- Fence Controllers are to be housed in a secure container, within the Listed Buildings compound, as per the ZPC's instructions.

- The electric fence shall be designed as a clear-view fence

Clearvu mesh Anti-cut Anti-climb Fence

| Particulars | requirements |

| Fence length | 3700m |

| Fence height m | 2400mm |

| Panel size (Height x Width) | 2400mm x 2515mm |

| Fence Post (Height x Size x Thick ) | 3100mm x 60 x 60 x 4mm |

| Clamp Bar (Height x Width x Thick ) | 2400 x 60mm x 5mm |

Clearvu mesh panel size |

|

| Mesh pattern: | 76.2mm (3") x 12.7mm (0.5") resistance welded well at each intersection |

| Wire diameter | 4mm horizontal wire and 6mm vertical Wire |

| Weld strength | range 540-690 N/m2 |

| Surface treatment | Clearvu mesh fence panels made from galfan wire (or better material), then PVC powder coating (Min. 100 microns). Or PVC powder painting. It provides additional protection and increases the potential life span. |

| Colours | Green 6005 |

| Installation | Overlapped 75mm minimum at each Post as the following pictures below) for securing with slotted clamp bars and M8 diameter bolts. |

Fence posts |

|

| Material | High-grade steel for maximum strength and rigidity. |

| Post Plate thickness | 4.0mm |

| Finish | Inside and outside, hot dipped galvanized (Min. 275 g/m2), subsequently covered with a polymer powder (Min. 60 microns). |

| Post-cap | metal caps |

| Clips and clamps | Metal clips and clamps are galvanized hot dips and powder coated in green or black. |

Fence Gate |

|

| Number of Gates | 6 |

| Type of gate | Automated Heavy-Duty Swing Gate |

| Height | 2400mm |

| Width | 6 metres |

Specification Clearvu Fencing

| Height | Length | V-Bends |

| 1800 | 3000 | 3 |

| 2000 | 3000 | 3 |

| 2100 | 3000 | 3 |

| 2400 | 3000 | 4 |

| 3000 | 3000 | 5 |

| Wire diameter | Aperture 76.20mm | Tensile strength | Weld strength |

| 4mm (Vertical) x 3mm (Horizontal) 4mm (Vertical) x 4mm (Horizontal) 3mm (Vertical) x 3mm (Horizontal)

|

12.7mm high security 25mm medium security 50mm low security |

500 - 650 mpa | 60% - 80% |

| Zinc coating | ||

| Lightly Galvanised (60g/m²) | Fully Galvanised (275g/m²) | Galfan Coated (220g/m²) |

| Lightly Galvanised (50g/m²) | Fully Galvanised (255g/m²) | Galfan Coated (195g/m²) |

| Colour coatings | ||

| Powder Coating (60-80 microns) |

Thermal Plastic (250 microns min.) |

95%Zinc, 5%Aluminium |

Electric Fence (bolted to the Clearvu anti-climb fence)

The electric fence is tabulated below.

| Particulars | requirements |

| Electric Fence length | 3700m |

| Electric Fence height | 3400 mm |

Energizer |

Specifying the energizer will follow IEC 60335-2-76, the International Standard. The peak value of input voltage must be above 7.5kV but not exceeding 10kV |

Trip Wire Fence |

The average trip wire uses a Y -y-standard steel pole of 600mm. When the Post is planted, the height above ground level should be 280-300mm. Distance from Clearvu mesh fence: 600mm, where a short offset bracket can be used on the same side as the trip wire. |

Gates |

8 x 6m gates fitted |

Fence wire |

Positive wires should be "hot, double dipped" 2.4 mm nominal diameter, whilst negatives should be an average high tensile of 2.25mm nominal diameter. |

High Tension (HT) Insulated Cables |

Double-insulated HT cables must connect the energizer output connectors to the fence conductor wires. |

Crimp Ferrules / Split Bolts |

The fence wire and the High Voltage cable should be connected with suitable aluminium crimp ferrules. These components shall have the same material composition as the fence wire and the High Voltage cable |

Tensioning Devices |

•A non-metallic tensioning device should be used to tension the electric fence wires. •The tensioning devices should withstand at least five times the maximum installed wire tension. •The tensioning device should allow for the accurate tensioning of the fence wires to the required tension. It should only be possible to tension the fence wires utilizing a unique made tool which should indicate the correct wire tension |

Strain posts |

• All strain posts should be manufactured from 50mm x 50mm square tubing. • Strain posts should be fully galvanized/powder coated. All holes should be pre-drilled before galvanizing/coating. |

Intermediate posts |

• All intermediate posts will be manufactured from 25mm x 25mm square tubing • Intermediate posts should be fully galvanized/powder coated. All holes should be pre-drilled before galvanizing/coating |

Lightning Protection Specifications |

• The electric fence should be fitted with the appropriate lightning protection system following SANS 62305 Protection against lightning. • Protection should be provided on both the high voltage output and the 230VAC input. |

Lightning Diverters |

Adequate Lightning diverters shall be installed to prevent damage to the system by lightning |

Electric Fence flashers |

Flashes with every fence pulse Visible for up to 100m at night and 20m by day high brightness LEDs for long life and extra brightness Continuous monitoring Designed to be connected between live and earth fence wires Stainless steel connecting wires May reduce fence voltage by up to 0.3 kV Sealed weatherproof unit no maintenance or batteries required It can be placed anywhere on the fence Blue in Colour |

Earthing |

Earth pegs used at the beginning or end of each zone. At a maximum distance of 50m apart. Earth pegs connected to the central earth rod, the fence posts and the earth conductors of the fence. Three (3) earth pegs, 1.8m apart in a triangle layout, must be installed at both sides of the Access Control Building (ACB). The pegs must be connected to the central earth rod and the first Post on each side of the fence. |

Standards |

BS 1722:17, BS EN ISO 60335-2-76 |

Additional Features Clearvu Fencing

The strain and intermediate Post shall be a minimum 2mm thick steel post. Fully galvanized to meet BS EN ISO 1461. The Post is to be pre-drilled at 91 mm centres for the length of the Post. With additional mounting holes to allow the posts to be bolted to the host fence.

All holes and cuts are to be performed before galvanizing.

The expiration is to conform to BS 1 722: 17.

Strain Insulators for End or Corner Posts: Made of High-quality Industrial Plastic Virgin Nylon rated for 15KV UV Stabilized. Reel Insulators: Made of virgin Polypropylene plastic rated for 1 5K V UV stabilized". The design of the insulator shall be such that:

- 1. When the weak claw snaps off, the wire gets trapped between the Post and the insulator, thus creating an alarm condition.

- 2. When the Wire is tensioned, it cannot be removed from the insulator.

- 3. The securing pin is locked in position and is difficult to remove without significant force.

The strain insulator shall be manufactured from a high-density polymer, military green in colour, and fully UV stabilized to prevent degradation. The insulator shall be able to withstand tensions above 601kg. And shall provide adequate insulation between the fence post and the live wire. The tensioning filter, including the wheel and locking device, shall be manufactured entirely from a high-density polymer; military green in colour and fully UV stabilized to prevent degradation. The tensioning wheel shall, at minimum, have 30 incremental positions per complete only to allow for fine tensioning and adjustable with a ratchet tensioner.

The high voltage gate switch (HVGS) shall be manufactured from a heavy, durable plastic suitably reinforced for use on Clearvu Mesh fencing and heavy gates. The design of the HVGS shall be such that:

- 1. It will be possible to take the zone feed and return it through the switch.

- 2. The earth is incorporated into the body of the switch.

- 3. A dead short is placed across the zone when the gate opens. To prevent bypassing the switch.

For internal comers, the Pull-Througlfwheel shall be manufactured from a high-density polymer, military green in colour, and fully UV stabilized to prevent degradation. The wheel shall allow retrospective installation after the wire has been strung and be suitable for any internal angle horizontally. The wheel design shall be such that it allows even tensioning across the elevation.

The lead-out cable shall consist of a steel wire. Diameter 2.7mm, with a resistance of no more than I l ohms per kilometre. The cable shall be encased in a double insulation rated for 15kv isolation and made of a material suitable for pulling through ducts without damage to the insulation.

The warning signs manufactured and displayed on the fence according to BS EN ISO 60335-2-76 and BS 1722:17

General Construction Specification

The electric fence shall comprise a minimum of 38 high tensile wires strung between two strain points at intervals of no more than 91mm vertically, from ground level up to a height of 1000mm minimum above the height of the physical host fence in all areas.

- The height of the electric fence is to be 3.4m

- The bottom wire of the electric fence shall be no further than 125mm from the concrete steel ground.

- All electric fence wires, either live or the earth, shall be a minimum of 30mm from any steelwork on the physical fence or otherwise to prevent potential short circuits and subsequent nuisance alarms.

- The warning signs attached to the physical fence, not the electric fence wires.

- Double-leaf gates zoned independently and fitted with a High Voltage Gate Switch (HVGS).

- Emergency egress gates should be designed and configured as independent zones or may be incorporated into the adjacent zone if they are seldom used. Still, in both cases, the gate must be fitted with an HGVS. Details are to be supplied at the site visit.

- All strain points shall be externally protected by anti-climb configuring to be fitted in series at all times. The number of anti-climb wires will be a minimum of 6

- All intermediate posts shall be fitted with a 'weak-claw' insulator.

- All fence controllers shall be sited so that the zones are fed directly from the fence controller via ducting or equivalent to the zone start strain point and shall be appropriately housed in a building or purpose-built IP68-rated external cabinet. The ZPC will detail the exact position of the Controller and critical pad at the site visit.

Control and Operation Clearvu Fencing

- Control and monitoring the electric fence shall be done via a central station.

- Provision for connecting the electric fence to the CCTV system should be available.

- On Each zone Controller. Each fence output is programmable and can monitor a separate zone of the fence. In a security breach, the system identifies the zone in which the alarm has occurred.

- High Voltage Zone Separation shall ensure that if an intruder attacks one zone of the fence, the performance of the remaining zones will not be affected in terms of voltage and detection capability.

- Selectable Zone Control: The Controller can exclude fence zones from the system to allow for partial arming of the site.

- Smart Battery Backup: In the event of mains power failure, the system will automatically switch over to the backup battery system. While powered by the battery, the system will monitor the power failure's duration and the battery's condition. The Controller can support the fence in High Voltage mode for 8 hours.

Supply Clearvu Steel Work For Airport Clearvu Fencing

- 3mm, hot dipped galvanized high tensile steel wire to the pre-drilled holes in the Reinforced concrete post in three lines to receive welded mesh per BS 1722.

- Three lines of strand galvanized barbed wire (3mm) in equal rows to the pre-drilled r.c posts,3mm, hot dipped galvanized.

- Coiled razor wire of 600mm diameter fixed to three lines of strand galvanized barbed wire(3mm) in equal rows to the pre-drilled Reinforced concrete posts

.Fence posts shall be provided with double-cranked extension arms as described in BS 1722 (10). - 2400mm high galvanized welded mesh anchored into the concrete at the bottom along the entire length per BS 1722 Part 10. It is a 2.4-meter high fence with an additional 0.3-meter buried beneath ground level (2.7 meters total). The mesh shall be 3mm diameter steel wire, zinc coated with an outer plastic sheath.

- Supply and fix standard steel gate welded 50x25mm hollow section frame with 25x12.5mm hollow section stirrups and bracing double swing 2100mm high by 6m wide complete with an ironmonger.

COLORS AVAILABLE Clear View Fencing

High-security fence papular colours

High-security fence available colours

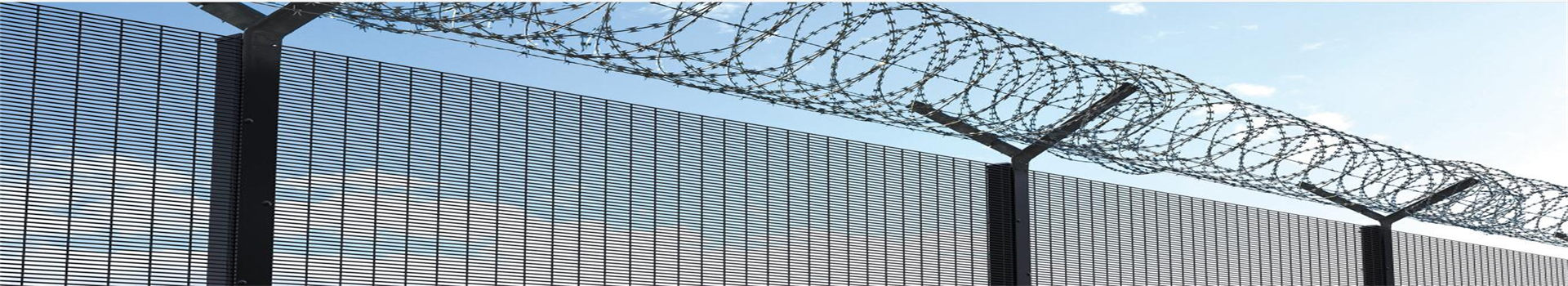

Clear-view fence pictures

|

High-security fence with spikes |

Green colour high-security fence |

Hot dip galvanized high-security fence |

Blue colour high-security fence |

|

Vertical mesh high-security fence |

clear view fencing with razor wire |

Clearvu fence for Warehouse |

Gates |

Clearvu welding wire mesh topped razor wire for airport fencing.

Clearvu Anti-climbing Mesh Security Fence

High-Security Fence with Electric Fence, CCTV system and gates for prison and other uses

Packing & Loading

- 1> There is a piece of plastic film(with tiny bubbles); the first panel can be prevented from damaging the metal pallet

- 2>Metal plate is fixed at each corner of the panels, keeping the panels together and immovable.

- 3> there is a plastic film between two fence panels, which will prevent the friction and collision of each fence panel.

- 4> The wood plate on the 358 anti-climb fence panels can prevent the last panel from being damaged by the top pallet

|

|

|

Products Category

- Clear Fence

- Clearview Fencing

- Chain Link Fence

- Temporary Noise Barriers

- Wall Spikes

- Aluminium Fence

- weld mesh fence

- ClearVu Fencing

- Clear View Fencing

- razor wire mesh

- Clear View Fence

- Clearvu Fence

- weld wire mesh

- 358 mesh fence

- palisade fence

- Steel Fence

- Crowd Control Barriers

- Temporary Fence

- Dog Kennel

Contact Us

Name: FRANK

Tel: 0086-318-7883678

Fax: 0086-318-7883678

Mobile: +86-17121115666

E-mail: sales@clear-view-fencing.co.za

Skype: MR.WIREMESH

QQ: 9651140

WeChat: wirefence

Whatsapp: 8615690482714

Add: A108 ZIWU INDUSTRIES ZONE ANPING COUNTY HENGSHUI CITY CHINA

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online